Submerged Arc Longitudinal Welded (LSAW/SAWL) Pipe

Submerged Arc Longitudinal Welded (SAWL) Pipe is a kind of tubular product having one or two longitudinal seams produced by the submerged-arc welding process.

Submerged Arc Longitudinal Welded (SAWL) Pipe is mainly used in onshore and offshore oil & natural gas, shale gas, ore slurry transportation, tap water, sewage, heating network reconstruction and other projects, and it is also widely used in piling, bridges, steel structures, etc.

Size

Diameter: Ф406.4~Ф1626mm (8.62"-64")

Wall thickness: 6.3~60mm (1/4"-3")

Steel Grade

Pipeline steel: B~X100 (API 5L), L245~L690 (GB/T 9711)

Carbon steel: Q235~Q460, C60, C65, etc.

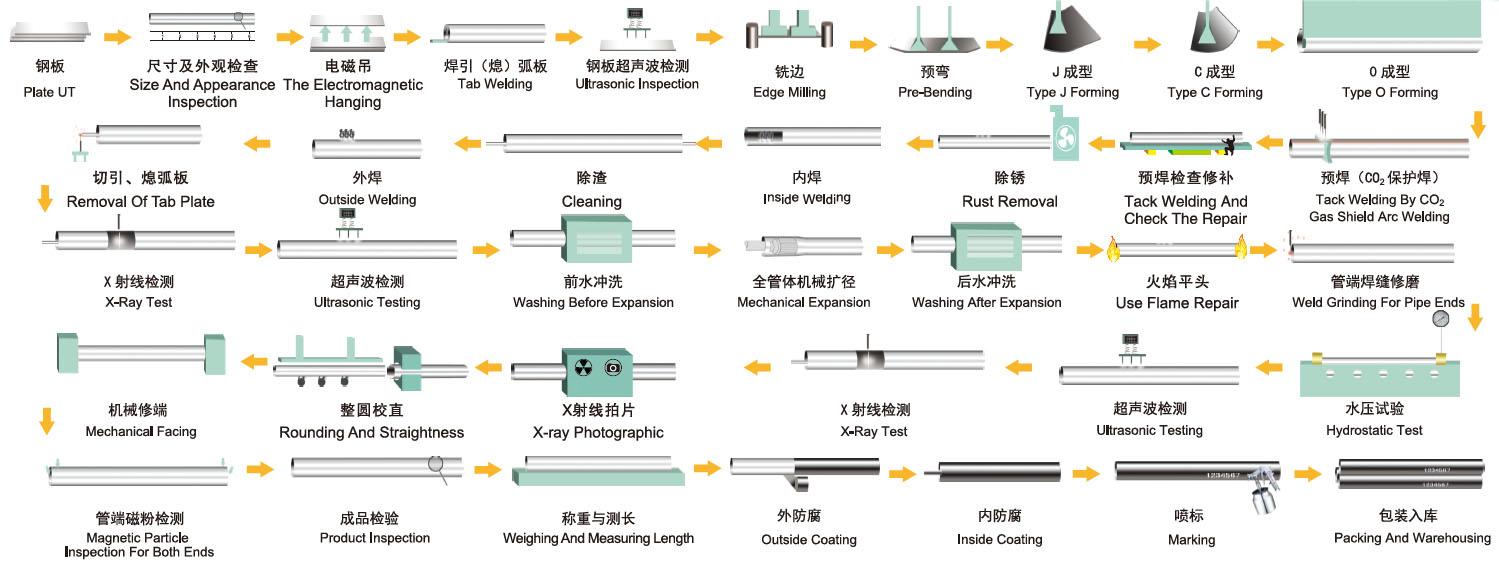

LSAW Pipe / SAWL Pipe Manufacturing Process Flowchart

Applied Standards

API Spec 5L (46 edition) Specification for Line Pipe

GB/T 9711-2017 Petroleum and natural gas industries—Steel pipe for pipeline transportation systems

GB/T 3091-2015 Welded steel pipes for low pressure liquid delivery

SY/T 5037-2018 Spiral submerged arc welded steel pipe for pipelines for low pressure fluid service

SY/T 5040-2012 Welded steel pipe piles

ASTM A671 Standard Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures

ASTM A672 Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures

ASTM A53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A252 Standard Specification for Welded and Seamless Steel Pipe Piles

ASTM A500 Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

ASTM A139 Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

ASTM A691 Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

Other standards of similar products and other higher standards (DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA, etc.)

Outside Diameter and Wall Thickness of Submerged Arc Longitudinal Welded (LSAW/SAWL) Pipe

|

Outside Diameter |

Wall Thickness |

|

Length(m) |

|

Inch |

mm |

Min.Yield Strength(Mpa) |

|

|

245(B) |

290(X42) |

360(X52) |

415(X60) |

450(X65) |

485(X70) |

555(X80) |

690(X100) |

|

16 |

406 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.0 |

6.0-10.5 |

6.0-10.0 |

6.0-9.0 |

6.0-9.0 |

6.0-12.3 |

|

18 |

457 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.5 |

6.0-11.0 |

6.0-10.0 |

6.0-10.0 |

6.0-12.3 |

|

20 |

508 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.5 |

6.0-12.0 |

6.0-11.0 |

6.0-11.0 |

6.0-12.3 |

|

22 |

559 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.5 |

6.0-13.0 |

6.0-12.0 |

6.0-12.0 |

6.0-12.3 |

|

24 |

610 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.5 |

6.0-14.0 |

6.0-13.0 |

6.0-13.0 |

6.0-12.3 |

|

26 |

660 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-15.0 |

6.0-14.0 |

6.0-14.0 |

6.0-12.3 |

|

28 |

711 |

6.0-20.0 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.5 |

6.0-16.0 |

6.0-15.0 |

6.0-15.0 |

6.0-12.3 |

|

30 |

762 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.0 |

7.0-17.5 |

7.0-17.0 |

7.0-16.0 |

7.0-16.0 |

6.0-12.3 |

|

32 |

813 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.5 |

7.0-18.0 |

7.0-17.0 |

7.0-17.0 |

6.0-12.3 |

|

34 |

864 |

7.0-23.0 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.5 |

7.0-19.0 |

7.0-18.0 |

7.0-18.0 |

6.0-12.3 |

|

36 |

914 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.0 |

8.0-20.5 |

8.0-20.0 |

8.0-19.0 |

8.0-19.0 |

6.0-12.3 |

|

38 |

965 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.5 |

8.0-21.0 |

8.0-20.0 |

8.0-20.0 |

6.0-12.3 |

|

40 |

1016 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

8.0-21.0 |

6.0-12.3 |

|

42 |

1067 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

8.0-21.0 |

6.0-12.3 |

|

44 |

1118 |

9.0-27.0 |

9.0-26.0 |

9.0-24.5 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

9.0-21.0 |

6.0-12.3 |

|

46 |

1168 |

9.0-27.0 |

9.0-26.0 |

9.0-24.0 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

9.0-21.0 |

6.0-12.3 |

|

48 |

1219 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.0 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

9.0-22.0 |

6.0-12.3 |

|

52 |

1321 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.2 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

9.0-22.0 |

6.0-12.3 |

|

56 |

1422 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

10.0-22.0 |

6.0-12.3 |

|

60 |

1524 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

10.0-22.0 |

6.0-12.3 |

|

64 |

1626 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

10.0-23.0 |

6.0-12.3 |

|

68 |

1727 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

10.0-23.0 |

6.0-12.3 |

|

72 |

1829 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

10.0-23.0 |

6.0-12.3 |

Tolerance of Outside Diameter and Wall Thickness of SAWL Pipe

|

Types |

Standard |

|

SY/T 5040 |

SY/T 5037 |

GB/T 9711 |

ASTM A252 |

AWWA C200 |

API 5L PSL1 |

Pipe End

OD Deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall Thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm<t<15.0mm, ±0.11 |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

Chemical Composition and Mechanical Properties of SAWL Pipe

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|

C |

Mn |

Si |

S |

P |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

|

GB/T 700 |

A |

0.22 |

1.4 |

0.35 |

0.05 |

0.045 |

235 |

370 |

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

C |

0.17 |

1.4 |

0.35 |

0.04 |

0.04 |

235 |

370 |

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

GB/T 1591 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

B |

0.2 |

1.7 |

0.5 |

0.03 |

0.03 |

345 |

470 |

|

C |

0.2 |

1.7 |

0.5 |

0.03 |

0.03 |

345 |

470 |

|

BS EN 10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.05 |

0.05 |

225 |

340 |

|

ST44-2 |

0.21 |

- |

- |

0.05 |

0.05 |

265 |

410 |

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.04 |

0.04 |

345 |

490 |

|

JIS G3101 |

SS400 |

- |

- |

- |

0.05 |

0.05 |

235 |

400 |

|

SS490 |

- |

- |

- |

0.05 |

0.05 |

275 |

490 |

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |